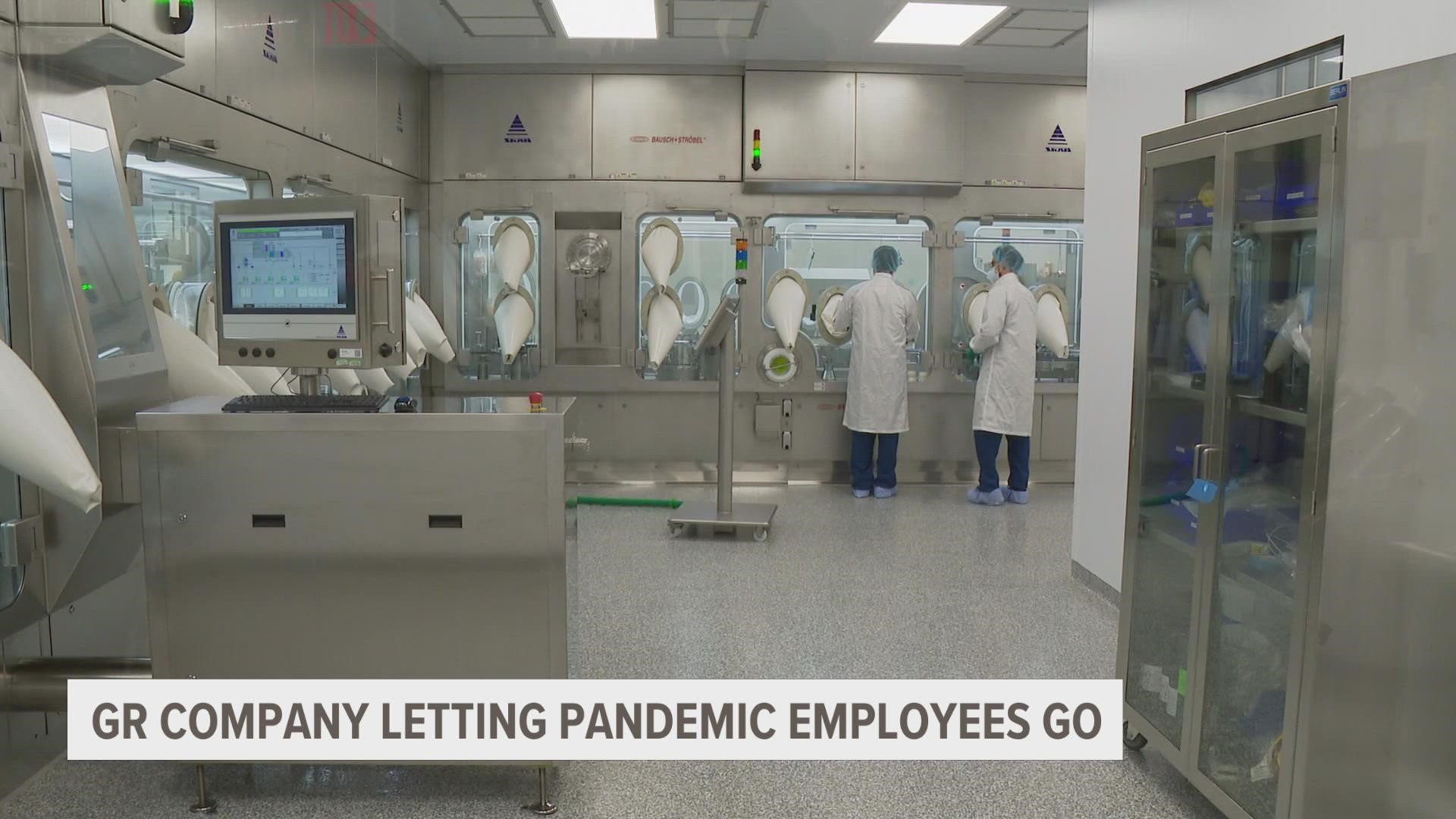

GRAND RAPIDS, Mich — Grand River Aseptic Manufacturing (GRAM) is restructuring some of its workforce in reaction to a global decline in demand for the COVID vaccine.

In August 2020, Operation Warp Speed selected GRAM to produce a vaccine. Then, it signed a contract with Johnson & Johnson to fill and finish its version of the vaccine.

GRAM's senior manager for marketing and public relations released this statement:

"Grand River Aseptic Manufacturing (“GRAM”) hired significantly beginning in August 2020 to support Operation Warp Speed and manufacturing a COVID-19 vaccine. The GRAM team quickly rose to the challenge of battling a pandemic and produced outstanding results that saved lives around the world. People came together like never before, and GRAM is grateful to have been a part of the journey. Now, market demand for COVID vaccinations on a global scale have drastically decreased, and as a result, the need to manufacture has decreased. These factors resulted in GRAM’s decision to restructure a portion of those additional people who GRAM hired during the COVID emergency. No other elements of GRAM are affected, and current expansions, partnerships, and activities are unchanged."

It is unclear how many employees the restructuring affects. However, GRAM said in 2021, 125 new positions were added for the J&J project, while planning to hire another 75 more later that year. They ranged from entry-level to experienced management.

A source close to the company said more than 100 employees lost their job in the last two months, 90 of them just this past Monday.

Earlier this year, GRAM signed a $120 million contract with the U.S. Department of Health and Human Services and U.S. Department of Defense. This allowed GRAM to invest in expansions of filling and finishing facilities.

In a press release in April, the contract "supports the build-out of floor two in GRAM’s aseptic filling facility, along with a 30,000 square-foot expansion of GRAM’s finishing center, including a sterility laboratory and added warehouse space. The agreement will increase GRAM’s filling capacity to a total of four isolator fill lines and further expands finishing operations with the advanced equipment and technology GRAM is well known."

RELATED VIDEO: Grand Rapids company plays role in Johnson & Johnson COVID-19 vaccine production

►Make it easy to keep up to date with more stories like this. Download the 13 ON YOUR SIDE app now.

Have a news tip? Email news@13onyourside.com, visit our Facebook page or Twitter. Subscribe to our YouTube channel.