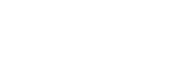

SPRING LAKE, Mich. — (Grand Haven Tribune) - NOCH employees are installing the hands-free door handles just as fast as Rich Lange can make them.

Lange, like a lot of other people, has a lot of time on his hands these days. The retired director of web experience for Priority Health has enjoyed extra time hanging out with his grandchildren via Skype, but he wanted to contribute something to help out during the coronavirus pandemic.

“I have always been a hobbyist, woodworker, gadget kind of guy,” Lange said last week. “I got into 3-D printers a few years ago.”

Lange said his a pair of inexpensive printers were sitting unused. He read about other people making masks with them, but decided that might not be the best way for him to go. Plus, hospitals are not accepting a lot of 3-D printed items.

As he explored 3-D options on the internet, Lange found a company, Materialise of Belgium, had several designs for items to make specifically in reaction to COVID-19. One of those items was an extension to a door handle, allowing someone to use their arm to open a door rather than place their fingers on the handle.

Lange obtained the design and printed one of the handle covers.

“It turned out fine,” he said. “Now I needed to figure out who could use these.”

Lange called the NOCH facilities director, Mark Reenders, and made arrangements to connect and see if the handle cover would work on doors at the hospital.

“We determined it needed a different design,” Lange said.

So, he took a hospital handle home with him, revised the pattern in his CAD program and it worked.

Lange said there are no licensing issues with the pattern as long as the company is credited for the design.

The handle extension is 6 inches long by about 1.5 inches wide, and takes about 2.5 hours to print, Lange said. He sets up his printers to do four at a time, then heads off to the computer to connect with his grandchildren.

Once a day, he heads over to NOCH with about 20 handle covers.

Lange said he is trying to refigure the printers to produce four more a day.

NOCH officials say the extenders will help with efforts to contain the spread of germs and viruses. NOCH spokesperson Jennifer VanSkiver noted that door handles are disinfected every 15 minutes, but a lot of hands could touch those handles during that time. The ability to use your forearm to open a door will help keep the spread of anything down, she said.

Reenders said the device is being put mostly in the administrative area, for now, and on door handles that get a lot of touches.

“We’re going to do about 60 doors,” he said. “They’re working great.”

Lange is fronting the cost of the handle extenders, which he said really isn’t much.

“A $20 spool of filament will do about 30 handles,” he said.

NOCH provides any hardware needed to attach the covers. The hospital will also print the labels that go with the handle covers: “Do less harm, use your arm.”

Lange encourages other people with 3-D printers to consider doing something like this to help out the hospital or other facilities.

RELATED STORIES:

- Holland Hospital presents: Great Minds Think Mindfully

- CALL 211 seeing spike in request for help, including essential workers with child care questions

- Here is a list of food pantries offering modified services amid COVID-19 restrictions

- Herman Miller reopens manufacturing to produce healthcare supplies

- Organizations freeing up space to act as relief sites amid COVID-19

►Make it easy to keep up to date with more stories like this. Download the 13 ON YOUR SIDE app now.

Have a news tip? Email news@13onyourside.com, visit our Facebook page or Twitter. Subscribe to our YouTube channel.